News

News

- What is a sacrificial anode

- Basic requirements for reference...

- What does the reference electrode do...

- Why are zinc blocks attached to the ...

- What is the principle of impressed...

- What material does metal structure...

Contact

Phone:18739187123

hotline:0391-7588881

E-mail:970512272@qq.com

Address:Wuzhi County, Jiaozuo City, China

Q & A

What are the characteristics of wrought magnesium alloy?

- Author:Libo

- Source:wm.americanfreedomlawncare.com

- Date:2021-06-11

- Click:0

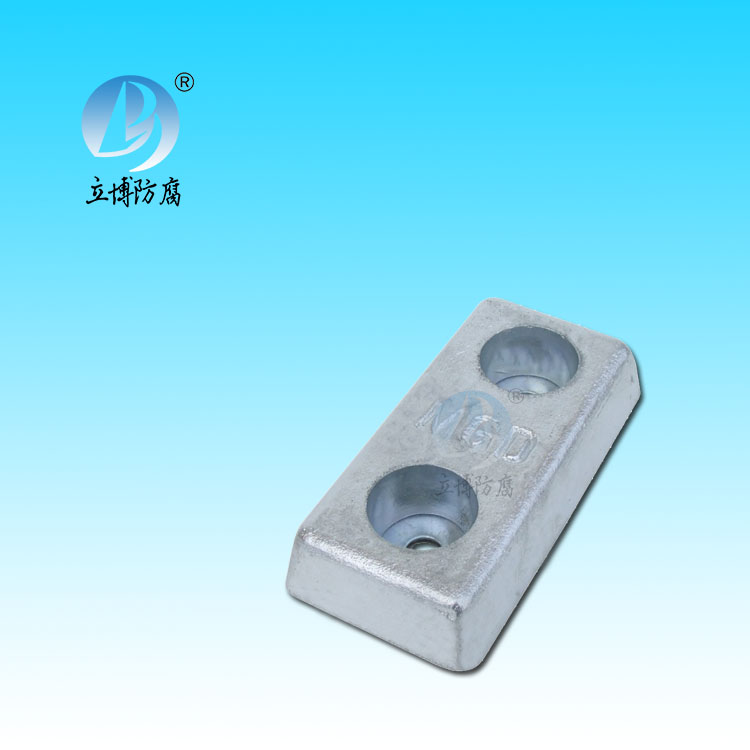

Wrought magnesium alloy is mainly used to produce magnesium alloy plate, extruded parts, forgings, etc., mainly used for structural parts.

The mechanical function of wrought magnesium alloy is closely related to the processing technology and heat treatment state. Generally, wrought magnesium alloy obtains the blank after melting and casting, and deformed the blank through extrusion, rolling, casting and other processes to obtain the profiles, tubes, plates and parts, so it is named wrought magnesium alloy.

For magnesium alloys, the difference in chemical composition leads to great difference in mechanical function, such as the big difference between AZ31 and AZ61. In general, the strength of magnesium alloys with high AL content is high, but its elongation is low. In heat treatment, magnesium alloy should be homogenized before deformation processing to eliminate internal stress and facilitate processing. After deformation, some of them need to be strengthened by heat treatment, while others cannot be strengthened by heat treatment due to the chemical composition. In addition, the slip system of magnesium alloy will change according to the different chemical composition. In a word, the chemical composition of magnesium alloy determines its mechanical function. The main prominent function of wrought magnesium alloy is change, which requires good ductility, yield strength and refined grains.

Die - cast magnesium alloy is mainly cast, the surface strength must be high. Source is: the book on magnesium alloy is Chen Zhenhua's process, Xu Riyao's smelting process.

客服QQ

客服QQ